GMP standard medicine fluid bed granulator dryer

$3000-4000 /Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Ningbo,Nanjing |

$3000-4000 /Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Ningbo,Nanjing |

Model No.: FL

Brand: Lead Macinery

Place Of Origin: China

Old And New: New

Machine Type: Granulator

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Plc, Pump, Motor

Warranty Period: 1 Year

Core Selling Point: Easy To Operate

Applicable Industry: Food &Amp; Beverage Factory, Energy &Amp; Mining

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Viet Nam, Mexico, South Korea, Kazakhstan, Italy

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, Germany, Pakistan, Argentina, Bangladesh, Tajikistan

Function: Granulating and drying

Application: Pharmaceutical, food and chemical

Size Of Granules: 40~100 meshes

Working Temperature: 60~120℃

Work Time: About 1.5h/ batch

Material: SUS304/ SUS316L

Heating Source: Steam/ Electricity

Control System: Touch screen / Button type

Explosion-proof: Custmized

Certificate: CE

1. General description of Fluid Bed Granulator

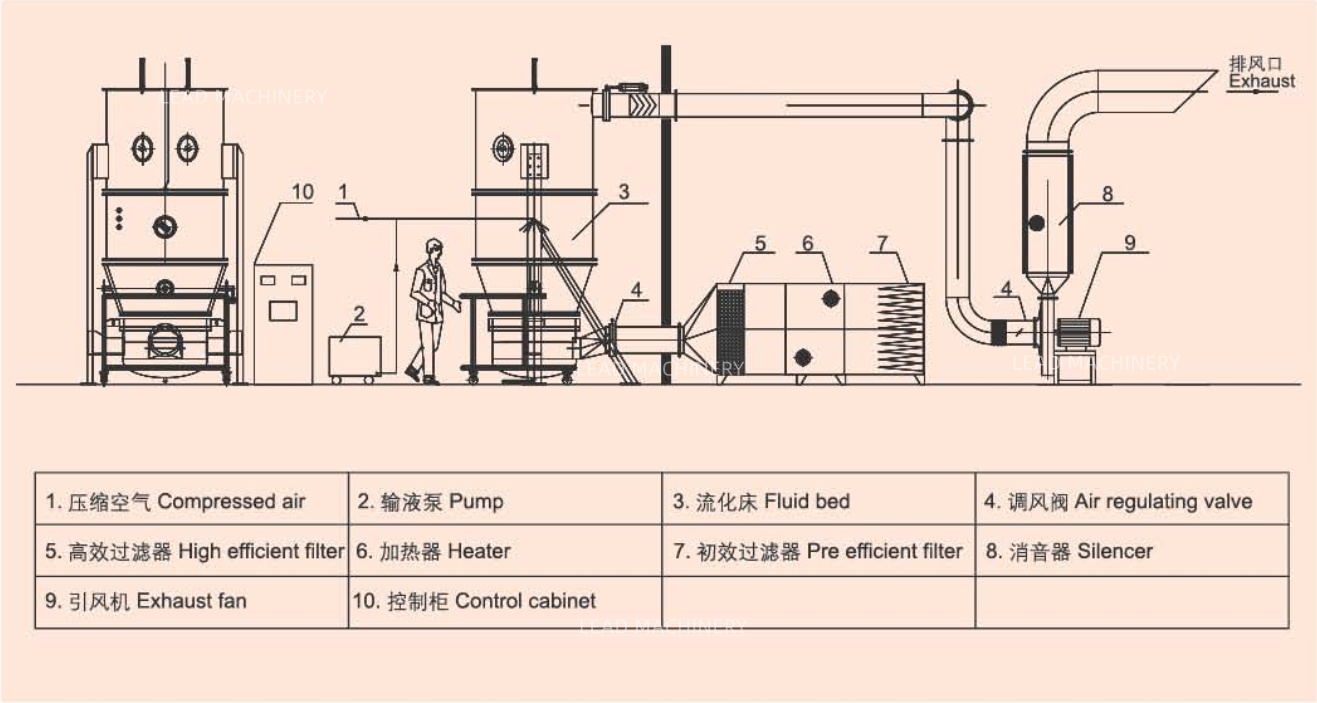

Fluid bed granulator is composed of main machine, air handling system, heating system, slurry handling system and control system. When it works, the materials are fed into the silo of the fluid bed granulator, and after the programs and parameters are set according to the process requirements, the machine starts to work. After filtered by the air handling system and heated by the heating system, the air enters the main machine. After going through the slurry handling system, the slurry is sent to the spray gun and sprayed to the materials inside the cavity, and then is bonded with powder to form granules. After the operation is completed according to the set programs and parameters, the silo is pushed out and connected with the lifting material transferring machine for lifting discharging or the Vacuum Feeder is used to pump the materials to a high position for granule sizing by the granule sizing machine, so as to effectively control dust pollution and cross contamination.

Pictures of Fluid bed granulator

2. Application of Fluid bed granulator

Fluid bed granulator is one of the process equipment commonly used in the production of solid preparations in the pharmaceutical industry. It has various functions such as mixing, granulating and drying. It is also widely used in such industries as medicine, chemical industry and food.

Granules that made by fluid bed granulator

3. Features of Fluid bed granulator

1. FL fluidized drying granulator through powder granulation improves the mobility and solubility as well as reduces the flying dusts.

2. The mixing, granulation and drying can be completed in the same fluidized Granulating Machine.

3. The antistatic filter cloth is used to ensure the security of equipment operation.

4. This fluidized drying granulator adopts pressure relief holes to ensure the safety of the facility and staff in case of the explosion.

5. Our fluidized granulating machines are without any dead angle as well as easy to load and unload materials.

6. This granulating equipment is easy to wash, conforming to the GMP standard.

Flow chart of Fluid bed granulator

4. Parameters of Fluid bed granulator

| Model | FL-3 | FL-5 | FL-15 | FL-30 | FL-60 | FL-90 | FL-120 | FL-200 | FL-300 | FL-500 |

| Volume of container (L) | 12 | 22 | 45 | 100 | 220 | 300 | 420 | 670 | 1000 | 1500 |

| Capacity (kg/batch) | 3 | 5 | 15 | 30 | 60 | 100 | 120 | 200 | 300 | 500 |

| Power of fan (kg) | 3 | 4 | 5.5 | 7.5 | 11 | 18.5 | 22 | 30 | 37 | 45 |

| Steam consumption (kg/h) | 15 | 23 | 42 | 70 | 141 | 180 | 211 | 282 | 366 | 451 |

| Pressure of steam (Mpa) | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 |

| Consumption of compressed air (m3/min) | 0.6 | 0.9 | 0.9 | 0.9 | 1.0 | 1.0 | 1.0 | 1.1 | 1.5 | 1.5 |

| Working temperature (℃) | 40~120 | 40~120 | 40~120 | 40~120 | 40~120 | 40~120 | 40~120 | 40~120 | 40~120 | 40~120 |

| Working time (min/ batch) | 45~90 | 45~90 | 45~90 | 45~90 | 45~90 | 45~90 | 45~90 | 45~90 | 45~90 | 45~90 |

| Product collecting rate | ≥99% | ≥99% | ≥99% | ≥99% | ≥99% | ≥99% | ≥99% | ≥99% | ≥99% | ≥99% |

| Weight of machine (kg) | 500 | 700 | 900 | 1000 | 1100 | 1200 | 1300 | 1500 | 1800 | 2000 |

| Size of output granules (mesh) | 40~100 | 40~100 | 40~100 | 40~100 | 40~100 | 40~100 | 40~100 | 40~100 | 40~100 | 40~100 |

| Moisture of output granules | ≤1.5% | ≤1.5% | ≤1.5% | ≤1.5% | ≤1.5% | ≤1.5% | ≤1.5% | ≤1.5% | ≤1.5% | ≤1.5% |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.