Wet type High Shear Mixer Granulator for Nutriceutical

$3000-30000 /Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Nanjing,Nongbo |

$3000-30000 /Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Nanjing,Nongbo |

Model No.: GHL

Brand: Lead machinery

Place Of Origin: China

Old And New: New

Machine Type: Granulator

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Plc, Gearbox, Motor, Bearing

Warranty Period: 1 Year

Core Selling Point: High Productivity

Applicable Industry: Food &Amp; Beverage Factory, Energy &Amp; Mining, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Canada, Philippines, Japan, Algeria, Uzbekistan, India, Italy

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Canada, Philippines, Spain, Algeria, Uzbekistan

Function: Wet granulation

Application: Pharmaceutical, food and chemical

Material: SUS304/ SUS316L

Control System: Touch screen/ Button type

Feeding Type: Vacuum feeder/ Bin lifter/ Manually

Explosion-proof: Customized

Certificate: CE

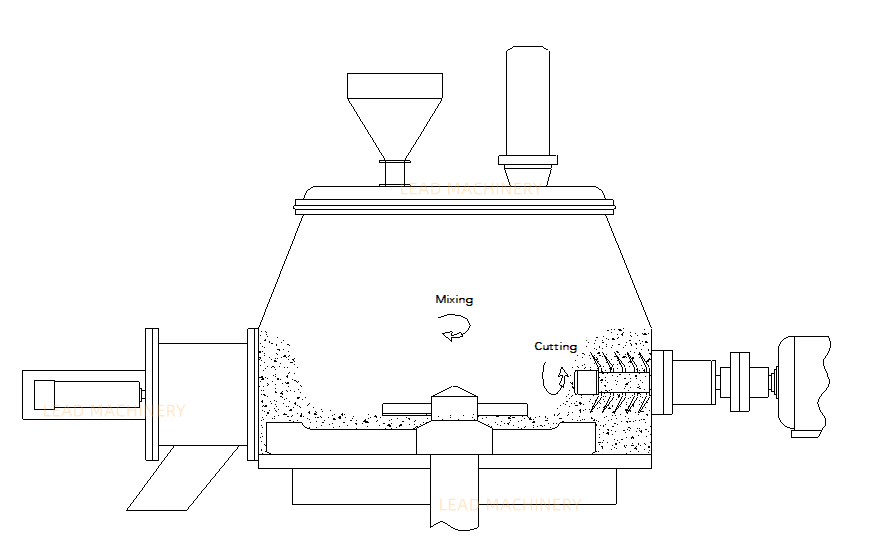

1. Work principle of High Shear Mixer Granulator

High Shear Mixer granulator is wet method mixing and Granulating Machine. The powdery material and adhesive in cylinder are mixed completely at the bottom of the machine to achieve humid-soft material, and then cut by a high speed chopper to become similar spherical granules.

Liquid binder is usually fed into the closed container with a Rapid Mixer and a chopper. The result is that the liquid binder and solid will be formed into dense granules.

2. Application of high shear mixer granulator

High shear mixer granulator is widely used in the process of material mixing and granulation in pharmaceutical, food, chemical, pesticide and other industries. The granules are conducive to tablet pressing and capsule filling.

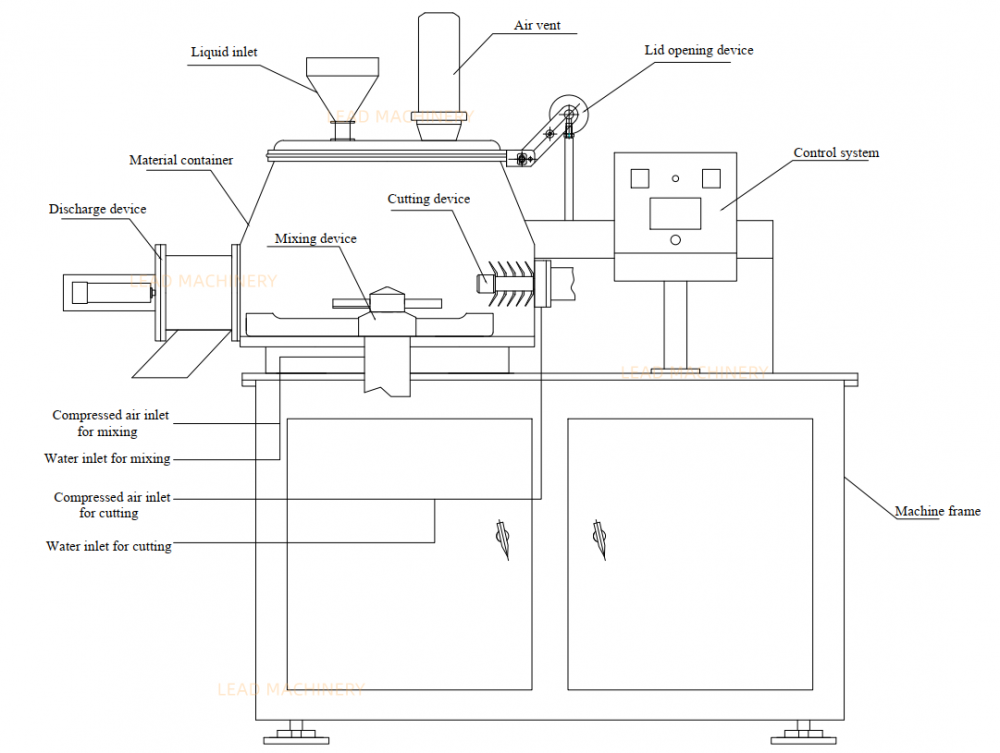

3. Main structure of high shear mixer granulator

3.1. Equipment composition of high shear mixer granulator

This machine is mainly composed of a machine frame, a container with a cover, a mixing system, a cutting system, a discharging device, a control system, a water and gas system, etc.

3.2. Machine frame of high shear mixer granulator

It is welded by section steel, and the frame is covered with stainless steel plate. The chassis frame is divided into upper and lower parts. The bottom is equipped with adjustable support feet and shock absorption sizing blocks. The upper frame supports the container with cover, mixing system, cutting system, and discharge device. The lower frame mainly carries the reducer, motor, and transmission system. The electrical control main board is placed in the lower frame. The frame material is Q235-A. The three sides are equipped with a protective cover plate, and the other side is equipped with a movable door made of a protective cover plate. The material is SUS304.

3.3. Container with cover of high shear mixer granulator

The container is an inverted cone, the bottom center is equipped with an agitator, the side is equipped with a granulating cutter, and the upper part is equipped with a quick opening cover; The quick opening cover is composed of a cover, a cover opening fixed arm, a cover opening rotating arm, an air cylinder, etc. The cover is provided with a feeding port, a sight glass, and an air vent. Material of container is SUS304 or SUS316L.

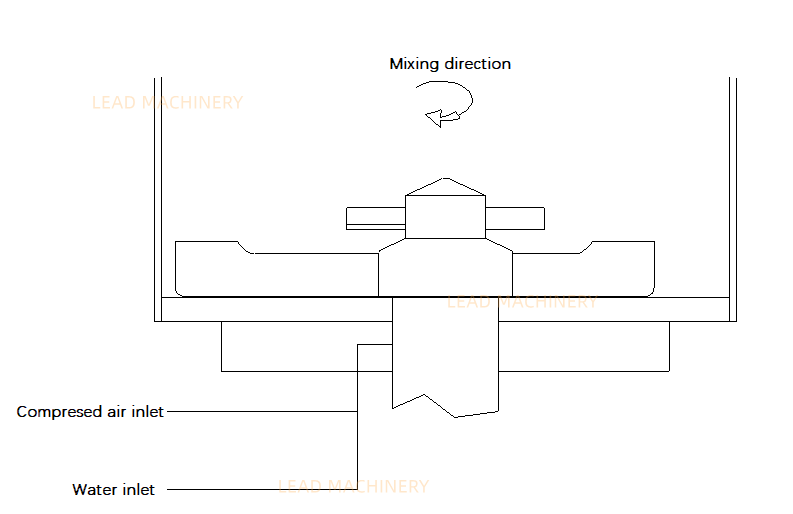

3.4. Mixing system of high shear mixer granulator

Mixing system: it is composed of motor, reducer, transmission shaft, mixing blades, compressed gas seal device and a rotary air gap seal. The material is 45# steel and SUS304. (Or SUS316L)

3.5. Cutting device of high shear mixer granulator

It consists of motor, transmission parts, multiple U-shaped cutters, and air sealing components, etc.

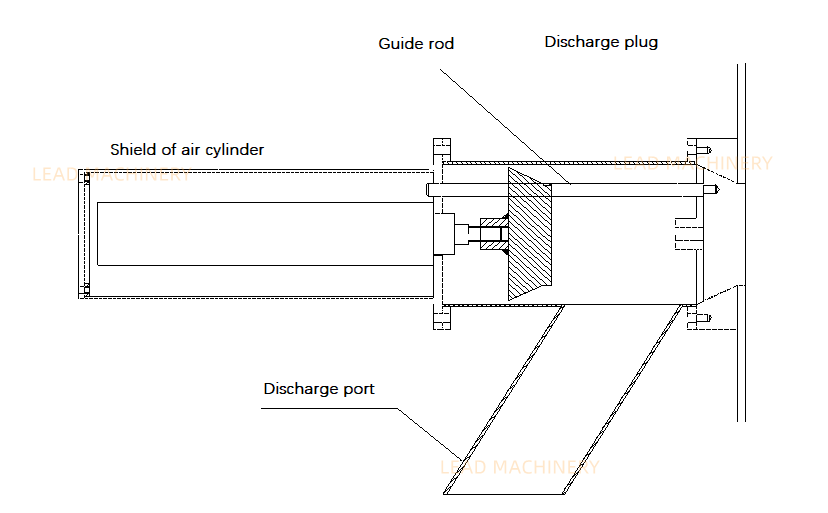

3.6. Discharging system of high shear mixer granulator

It consists of discharge seat, discharge plug, discharge port, guide rod and air cylinder, etc.

3.7. Control system of high shear mixer granulator

It consists of PLC, touch screen, inverter, electrical components, pneumatic components.

4. Features of high shear mixer granulator

Including dry mixing, wet mixing or wet mixing, cutting, granulating in the same sealed container.

Efficiency will be raised by 4~5 times compared with ordinary granulator.

25% adhesive can be saved compared with other ordinary granulating machine.

The mixing time per batch is about 2 minutes and granulating time is about 1~4 minutes.

The whole operation has strict safe and protective measures.

High speed chopper is used to break down the wet lump to produce granules.

The mixing speed is adjustable, running at a speed of 100~500rpm.

The cutting speed of chopper is adjustable, running at a speed of 1000~3000rpm, which makes the granules more even.

The final granules have medium density to high density with excellent flow and compression characteristics.

The granulation process is very quick and then usually transferred to a fluid bed drying machine for drying.

5. Parameters of high shear mixer granulator

Consumption of compressed air (m3/min) Pressure of compressed air (Mpa)

Model GHL-10 GHL-50 GHL-100 GHL-150 GHL-200 GHL-300 GHL-400 GHL-500 GHL-600 GHL-800 Capacity (kg/batch) 3 15 30 50 70 100 130 160 200 270 Mixing power (kW) 1.1 5.5 11 15 22 22 30 30 30 45 Mixing speed (rpm) 0~200

Cutting power (kW) 0.75 3 4 5.5 5.5 7.5 7.5 11 11 15 Cutting speed (rpm) 0~3000

0.2 0.4 0.4 0.6 0.6 0.9 0.9 1.0 1.2 1.5 0.6

Size of output granules (mesh) 20~80

Working time (min/ batch) 5~10

Weight (kg) 300 800 1000 1300 1600 2000 2100 2200 2700 3200

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.