GMP standard high shear mixer granulator for pharmaceutical

$3000-30000 /Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Nanjing,Nongbo |

$3000-30000 /Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Nanjing,Nongbo |

Model No.: GHL

Brand: Lead machinery

Place Of Origin: China

Old And New: New

Machine Type: Granulator

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Plc, Gearbox, Motor, Bearing

Warranty Period: 1 Year

Core Selling Point: High Productivity

Applicable Industry: Food &Amp; Beverage Factory, Energy &Amp; Mining, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Canada, Philippines, Japan, Algeria, Uzbekistan, India, Italy

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Canada, Philippines, Spain, Algeria, Uzbekistan

Function: Wet granulation

Application: Pharmaceutical, food and chemical

Material: SUS304/ SUS316L

Control System: Touch screen/ Button type

Feeding Type: Vacuum feeder/ Bin lifter/ Manually

Explosion-proof: Customized

Certificate: CE

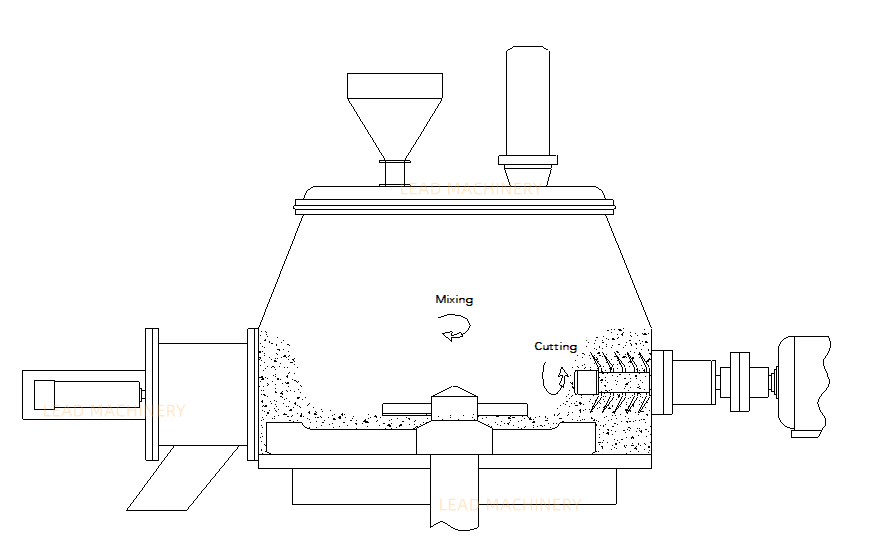

1. Work principle of High Shear Mixer Granulator

High Shear Mixer granulator is a process machine widely applied for solid preparation production in the pharmaceutical industry. It has such functions as mixing, granulating, etc. It has been widely used in such industries as medicine, food, chemical industry, etc.

2. Application of high shear mixer granulator

High shear mixer granulator is widely used in the process of material mixing and granulation in pharmaceutical, food, chemical, pesticide and other industries. The granules are conducive to tablet pressing and capsule filling.

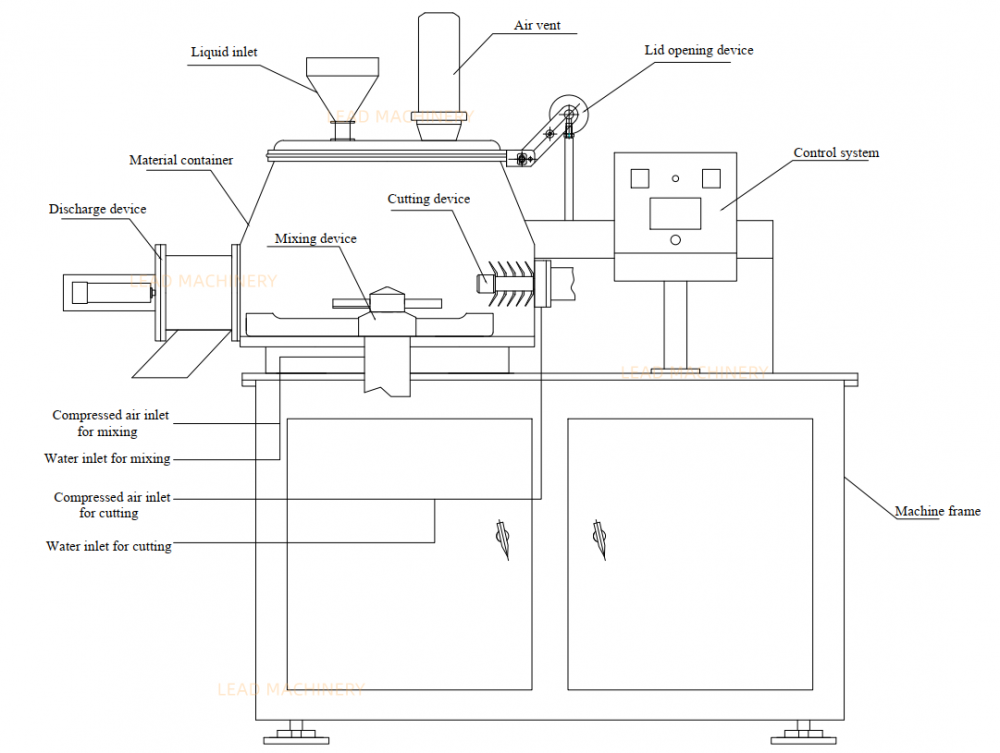

3. Main structure of high shear mixer granulator

3.1. Equipment composition of high shear mixer granulator

This machine is mainly composed of a machine frame, a container with a cover, a mixing system, a cutting system, a discharging device, a control system, a water and gas system, etc.

3.2. Machine frame of high shear mixer granulator

It is welded by section steel, and the frame is covered with stainless steel plate. The chassis frame is divided into upper and lower parts. The bottom is equipped with adjustable support feet and shock absorption sizing blocks. The upper frame supports the container with cover, mixing system, cutting system, and discharge device. The lower frame mainly carries the reducer, motor, and transmission system. The electrical control main board is placed in the lower frame. The frame material is Q235-A. The three sides are equipped with a protective cover plate, and the other side is equipped with a movable door made of a protective cover plate. The material is SUS304.

3.3. Container with cover of high shear mixer granulator

The container is an inverted cone, the bottom center is equipped with an agitator, the side is equipped with a granulating cutter, and the upper part is equipped with a quick opening cover; The quick opening cover is composed of a cover, a cover opening fixed arm, a cover opening rotating arm, an air cylinder, etc. The cover is provided with a feeding port, a sight glass, and an air vent. Material of container is SUS304 or SUS316L.

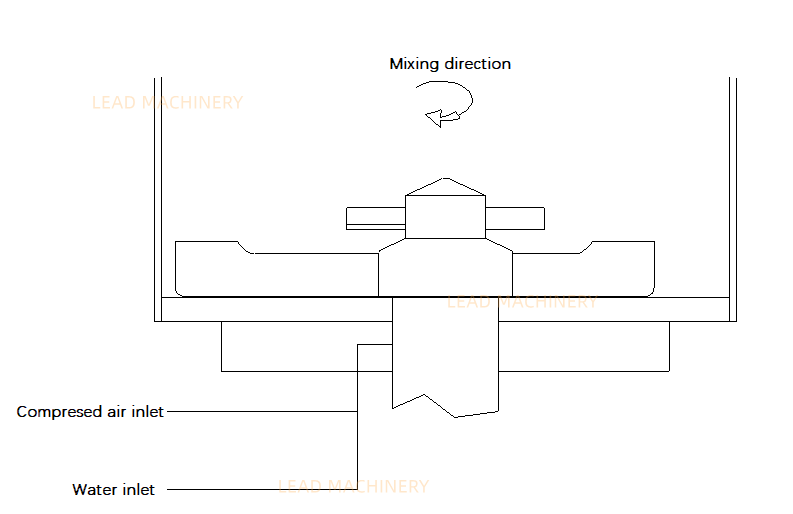

3.4. Mixing system of high shear mixer granulator

Mixing system: it is composed of motor, reducer, transmission shaft, mixing blades, compressed gas seal device and a rotary air gap seal. The material is 45# steel and SUS304. (Or SUS316L)

3.5. Cutting device of high shear mixer granulator

It consists of motor, transmission parts, multiple U-shaped cutters, and air sealing components, etc.

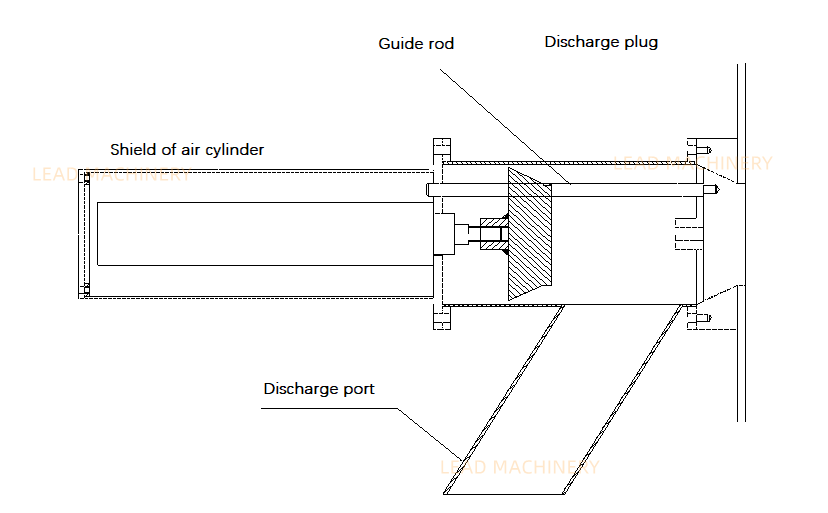

3.6. Discharging system of high shear mixer granulator

It consists of discharge seat, discharge plug, discharge port, guide rod and air cylinder, etc.

3.7. Control system of high shear mixer granulator

It consists of PLC, touch screen, inverter, electrical components, pneumatic components.

4. Features of high shear mixer granulator

It adopts Siemens PLC micro-computer control, human machine interface and touch screen to display the operations. The temperature, operating time, speed and formula are input to micro-computer and auto-controlled according to procedures, easy to operate with high automatic degree.

Add a set of V shape cutters on the basis of traditional straight shank cutter so that the cutters can action in both horizontal and vertical directions in material cutting process, which can reduce the granulating time. Cooperating with the unique mixing paddle of this machine, it's helpful to scrape away the attachment inner container to reduce the material sedimentation around container in-wall & at bottom and the collision to in-wall, at the same time, improve granulating efficiency and pelletized ratio, reduce the fine powder content below 8%. It adopts jacketed pot technique, which can heat or cool the material as required. The temperature in tank can be regulated by micro-computer automatically with temperature departure less than ±20C.

Provide the dripping device together with this machine. The adhesive addition can adopt dripping or direct mixing ways according to different requirements for different medicines, which can save around 20% consumption of adhesive, good effect of mixing granulation.

The safety protection device is complete and reliable. When the pot cover is under opening status, the main machine can only be started to operate by password and can't be started by other people so that ensure the safety of operators and machine. It can reserve vacuum feeding port at the part of pot cover, at the same time, equip with dedusting unit and adhesive filling port. We can monitor the granulating status in different stages through the sight glass to realize the non-dust operation in granulating process.

The cutter and revolving shaft of mixing paddle adopt double composite technology of rubber gasket with oil and spiral with air to seal, which completely solve the big problem of shaft seal easy to fail. The shaft seal is made into pulling type and can be dismounted, easy to maintain.

The mixing and granulating can be finished with one step, increasing the efficiency 4-5 times. The finished granules are solid with uniform size and high pelletized ratio. The granule size and bulk density can be adjusted optionally, suitable for the mixing granulation of Chinese herbal powders with big difference between chief herb and ingredients, Chinese medical extract, achieving good result.

5. Parameters of high shear mixer granulator

Consumption of compressed air (m3/min) Pressure of compressed air (Mpa)

Model GHL-10 GHL-50 GHL-100 GHL-150 GHL-200 GHL-300 GHL-400 GHL-500 GHL-600 GHL-800 Capacity (kg/batch) 3 15 30 50 70 100 130 160 200 270 Mixing power (kW) 1.1 5.5 11 15 22 22 30 30 30 45 Mixing speed (rpm) 0~200

Cutting power (kW) 0.75 3 4 5.5 5.5 7.5 7.5 11 11 15 Cutting speed (rpm) 0~3000

0.2 0.4 0.4 0.6 0.6 0.9 0.9 1.0 1.2 1.5 0.6

Size of output granules (mesh) 20~80

Working time (min/ batch) 5~10

Weight (kg) 300 800 1000 1300 1600 2000 2100 2200 2700 3200

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.